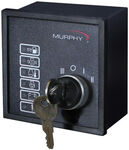

Murphy by Enovation KeyStart

by

From plug-and-play to fully configurable control, our Murphy PowerCore® Controller lineup is flexible for a wide range of engines and applications. Looking for auto start or manual start? Various throttling options? Mechanical or electronic engine control? Our rugged IP67 rated controllers and panels are all final Tier 4 /Stage IV ready and are up to the task.

From plug-and-play to fully configurable control, our Murphy PowerCore® Controller lineup is flexible for a wide range of engines and applications. Looking for auto start or manual start? Various throttling options? Mechanical or electronic engine control? Our rugged IP67 rated controllers and panels are all final Tier 4 /Stage IV ready and are up to the task.

by Murphy by Enovation

by Murphy by Enovation

by Murphy by Enovation

by Murphy by Enovation

by Murphy by Enovation

by Murphy by Enovation

by Murphy by Enovation

Palmer Johnson's nine-location factory-authorized service center network features: