Jastram Panoramic Rudder Indicator

by

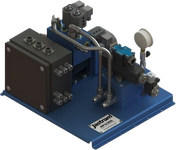

Palmer Johnson is proud to be an authorized distributor of Jastram’s steering systems. Whether you need spare parts or are interested in a new application, we are your top source for all Jastram steering systems needs.

If you are looking for a robust, durable, and low-maintenance line of steering systems, Palmer Johnson now has your solution with Jastram Engineering. Jastram is well known for its commitment to quality, from initial design to manufacturing to system commissioning and after-sales service.

Jastram is built on the understanding of how critical steering is to the operation of any vessel, which is why they design and manufacture to the highest quality. All steering systems are approached on a project-by-project basis. Their products range from simple manual steering for small vessels to digitally-controlled integrated systems for large ships. Steering systems are built with precision components carefully matched to ensure long life and exceptional performance in all operating conditions.

Jastram is able to design your steering system to meet all major marine classification rules and requirements. This means you have one less thing to worry about; the responsibility of obtaining steering gear classification is on us. In addition, Palmer Johnson and Jastram engineers are also available for commissioning and sea trails should owners or shipyards require this service.

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

by Jastram Marine Steering

Palmer Johnson's nine-location factory-authorized service center network features: