7 Things to Review When Repowering your Marine Vessel

Repowering your marine vessel with a modern low-emission engine is not only better for the environment but can also save you money in the long run. Making sure the transmission is efficiently integrated into the propulsion package is the key to success. Palmer Johnson Power Systems is here to help with all your repower needs.

1. Engine Rating Changes

New engines being used in repowers may incorporate a change in horsepower rating and peak RPM. These are considerations that could change the model and ratio of the marine transmission required for the application.

2. The Propeller

Propeller shape and design for the vessel should also be considered - as it is a key element to proper performance. The original propeller design is based upon the propulsion packages’ original engine rating and transmission gear ratio. Any change to this combination could lead to unsatisfactory vessel performance.

3. Torque Requirements

New engines have higher horsepower available to them at different RPMs, changing the torque requirements on the marine transmission. This means that an older transmission may not be suitable to work with a newer engine. Failure to address this could lead to early failure and significant damage or downtime.

4. Footprint and Fit

The current engine footprint is likely different than the replacement. Changes to the engine centerline should be addressed early on in the process, as the offset to the prop shaft is set by the marine transmission. Raising or lowering the engine could require modifications to the vessel. However, it is possible that a different offset in the marine transmission could help to resolve this issue.

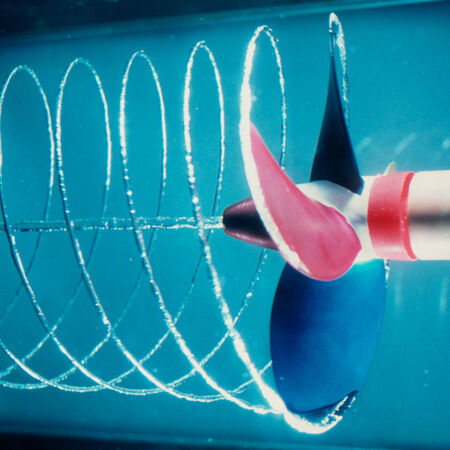

5. Torsional Vibration

In general, new engines are more torsionally active than older engines. The new transmission models include torsional couplings that dampen the high torsional activity of Tier 2, Tier 3, and Tier 4 engines. Without the proper torsional coupling vibration analysis, transmission life can be compromised. Torsional vibration failures are not covered under warranty and usually fail within the first 4,000-5,000 hours in service.

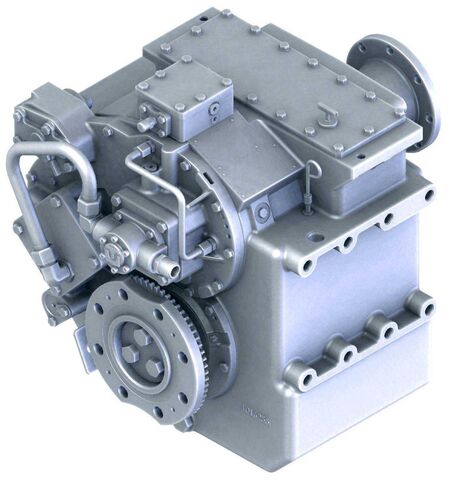

6. Obsolete Gears

Many older transmissions are obsolete and have been replaced with newer models; therefore, parts availability can be an issue. In addition, older transmissions coupled with newer engines could increase power demand issues, resulting in downtime. New transmissions come with a torsional coupling and a factory warranty to match your engine, ensuring long-term durability.

7. New Technology

Newer Twin Disc transmissions are available with electric proportioning valves that allow for more efficient shifting and electronic propulsion control systems, eliminating the possibility of operator error and clutch pack failure. They also provide a safer and more efficient operation at low speed. This option allows for better performance and maneuverability at low speeds, especially in trolling mode.

Keep Reading