How to Properly Lubricate your Twin Disc PTO

One way to get prolonged life out of your Twin Disc PTO is proper care and maintenance. Each Twin Disc power take-off has unique lubrication specifications that are important to follow. Taking the extra step and applying the appropriate amount of grease or oil at the Twin Disc recommended intervals can go a long way to ensuring that your PTO runs for years to come. You don't want to damage your components from unnecessary heat and grinding, which could happen if you don't lubricate properly.

Pro Tip: Do not over-grease your PTO! Excess grease can cause the main bearings to overheat and fail. When it comes to greasing your Twin Disc PTO, always follow the proper amount listed below.

Below we will outline the lubrication specifications for these Twin Disc Power Take-Off Models:

C106SP, C107SP, C108HP, C110HP, C111HP, SP111HP, SP211HP, SP211OP, SP311P, SP311OP SP114P, SP214P, SP214OP, SP214IL, SP314P, SP314OP, SP314IL, SP314S, SP218P, SP218OP, SP318P, SP318IL, SP318S, SP321P, IBF214P, IBF214OP, IBF314IL, IBF314P, IBF314OP, IBF314IL, IBF318P, IBF318OP, IBF318IL, IBF321P, IBF321OP, IBF321IL

If the model of PTO you are working on is not specified above, reach out to a Palmer Johnson representative for proper lubrication specifications.

Grease Specifications:

- Use NLGI Grade 2 grease with a minimum 149° C. (300° F.) drop point for all lubrication.

Oil Specifications for oil-lubricated main bearings:

- Use a good grade MS, DG, or better SAE No. 30 engine oil

Lubrication Locations:

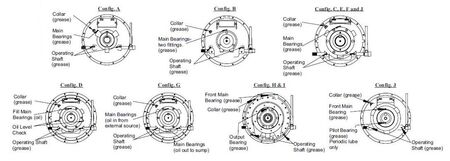

There are several different configurations depending on the model of the PTO. The below image displays the most common configurations for the various lubrication locations on a Twin Disc PTO.

Lubrication Overview:

Lubrication Instructions:

Main Bearings:

Models: C106SP, C107SP, C108HP, C110HP, C111HP, SP111HP, SP211HP, SP311P, SP114P, SP214P, SP214IL, SP314P, SP314IL, SP314S, SP218P, IBF214P, IBF314IL, IBF314P, IBF314IL, IBF318P, IBF318IL, IBF321P, IBF321IL

Apply 1 cc. of grease (one shot from a grease gun) before start-up and then every 8-10 hours of operation after that. Apply grease through the fitting on the bearing carrier or sheave housing.

Models: SP318, SP318S, SP318IL, SP321P

Check to see if there is a purge plug in the bottom of the bearing carrier. If a purge plug is not present, follow the above instructions for the list of PTO’s beginning with C106SP.

If a purge plug is present, remove the purge plug before grease is added. Add grease through the grease fitting until grease is visible in the open plug hole. Always rotate the shaft while adding grease to the bearing cavity. Run the PTO for 30 minutes until the excess grease drains out, then reinstall the plug.

Models: SP211OP, SP214OP, SP218OP, IBF314OP, IBF318OP, IBF321OP

The tapered roller bearings are lubricated from oil stored in an oil cavity in the bearing carrier. The oil level should be checked and maintained every 8-10 hours of operation. Drain and refill the oil cavity every 6 months or 1000 hours, whichever comes first.

Models: SP311OP, SP314OP

The tapered roller bearings are lubricated from engine oil continuously supplied through an orifice fitting in the bearing carrier. The oil drains back to the sump through an opening in the bottom of the bearing carrier. No periodic check is necessary.

Operating Shaft Fittings:

All Models

Apply 1 cc. of grease (one shot from a grease gun) before starting and then every 3 months or 100 hours of operation, whichever occurs first.

Throwout Collar:

All Models

Apply 1 cc. of grease (one shot from a grease gun) daily before start-p and then 8-10 hours of operation thereafter, through the fitting on the tapered part of the housing.

Pilot Bearing:

All Models With a Sealed-For-Life Style Pilot Bearing:

The sealed-for-life style of pilot bearing, which is the most commonly supplied style of pilot bearing, is pre-lubricated and sealed for life. No maintenance is required. Inspection is recommended every two years or when the power take-off is removed from the driving component for servicing.

All Models With a Greasable Style Pilot Bearing:

If the pilot bearing supplied with your power take-off is to be periodically lubricated, add one shot of grease gun every 100 hours through the fitting in the output end of the clutch shaft. Do not over-grease!

Clutch Linkage:

All Models

Lubricate the clutch linkage mechanism, cotter pins, clevis pins, and levers with engine oil every 500 hours of operation.

The PTO Experts

Following these Twin Disc recommended lubrication specs are critical to maximizing the life out of your PTO. If you have any additional questions, Palmer Johnson’s team of Twin Disc PTO experts are here to assist you with a wide arrange of questions. Call us today!

Keep Reading

PJ News

Twin Disc Discontinues RO PTO Line: Affected Models, Timeline, and What to Do Next

Twin Disc has discontinued the RO PTO product family effective January 2026. Learn which RO models are impacted, what replacement options exist, and how end-of-life support works.