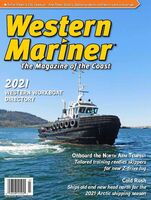

Veth Drives onboard the North Arm Tempest

This article was originally published in the July 2021 issue of Western Mariner Magazine. Palmer Johnson Power System is your Authorized Sales and Service Provider in Western Canada for Veth Propulsion products!

In early March 2021, North Vancouver-based ABD Boats launched North Arm Transportation’s most powerful tug yet — the 19.7 m (64'9"), 2,000 hp North Arm Tempest (see “North Arm Tempest” in the May 2021 issue of WM). In addition to being North Arm Transportation’s most powerful tug, the Tempest is also the company’s most maneuverable tug, with twin azimuthing drives and a forward hawser winch giving it the flexibility to act as ship docking tug in addition to its primary duties towing the 63.2 m (207'), 1,432gt fuel/cargo barge North Arm Genesis (2011, Dalian Lushun Binhai Shipping Repairing & Building Co., China) on the North Coast run. Because the Tempest is North Arm Transportation’s first Z-drive tug, it presented a bit of a learning curve for skippers Brendan Maxwell and Kyle Armstrong. Before putting the tug to work they took part in a tailored training program that included simulator training during the build, and hands-on training following the Tempest’s launch.

Impressive Specs

Designed by A. G. McIlwain, the North Arm Tempest is a near-sistership to Standard Towing’s ship docking tug Renegade, which was launched by ABD in 2012 (see “Renegade: Flexibility the Key to Standard Towing’s New Tug” by Rob Morris and Alan Haig-Brown in the July 2012 issue of WM).

Overall dimensions are 19.7 m LOA x 8.23 m x 4.2 m maximum draft (64'9" x 27'0" x 13'9"). Power is from twin Cummins KTA-38 main engines connected to VZ-900 azimuthing drives from Veth Propulsion (by Twin Disc). The engines are rated at 1,000-hp each in this application (their nominal rating is up to 1,200 hp each), and for improved efficiency, they’ll be governed down to 900 hp each during towing operations.

Twin John Deere 4045TFM85G24V fixed-speed auxiliaries from Frontier Power (Delta) provide electrical power (74 kW at 24 V), with front-mounted Logan Clutch PTOs and Kawasaki pumps powering the hydraulic systems, which were supplied by PSI Fluid Power (Richmond).

A pair of winches built by Burrard Iron Works covers the North Arm Tempest’s dual towing/ship-handling capabilities. On the bow is a split-drum combination anchor/ ship-handling hawser winch carrying 450 ft of 2-1⁄4"Amsteel Blue (a 350-ft mainline and 100-ft pennant) from Redden Net (Richmond). The aft towing winch carries 2,200 feet of 1-3⁄4" wire, consisting of a 1,400 ft. mainline and two 400 ft. pennant lines with tow socket and tow socket assemblies, and a 41 ton Skookum No. 320 BTA towline end shackle, supplied by Pacific Wire Rope (Surrey).

Accommodations

Below deck, there’s accommodation for six in four staterooms, plus a compact galley and settee/mess table, and a head/shower with separate laundry area, all finished by ABD in a light maple-colored fire rated laminate. “It’s a beamier boat than the Diligent, which we were using before on the North Coast run,” notes skipper Kyle Armstrong. “The extra beam means it has roomier bunks, providing a real improvement in comfort.”

One feature the crew really appreciates is a separate coffee nook between the galley and the mess table. “It’s a small detail that makes a big difference,” says Armstrong, “because it means you don’t get in the cook’s way when you just want to grab a coffee.” The crew also appreciates how quiet the boat is, thanks to its isolation-mounted wheelhouse and machinery. “It’s a helluva lot quieter than the Diligent,” comments Armstrong. Measurements commissioned by North Arm Transportation showed stateroom noise levels in the low 60dB range when towing, and some quick measurements with a smartphone app showed less than 75 dB in the galley while running free at 7.8 knots against an ebb current.

The tug is also remarkably vibration-free. “Overall, it’s a great space,” concludes Armstrong. “Pretty much the only thing I could think to improve things might be a little more room in the head compartment, as the shower is tucked in pretty tight.”

Z-Drive Training

As with most things over the past 18 months, training for the new tug was complicated by the Covid-19 pandemic. North Arm Transportation had contracted with Cpt. Jeff Slesinger at Delphi Maritime in Washington State to provide training (Slesinger literally wrote the book on Z-drive operation, published as ASD Tugs: thrust and Azimuth – Learning to drive a Z-drive 2nd Edition, ISBN 9780764356827, $44.95).

The classroom training aspects were accommodated online, but Slesinger wasn’t able to travel to BC for the simulator, and hands-on training, so retired Seaspan master Ryan Scott was enlisted to help out with that part of the program.

“We did two weeks in the simulator at the Pacific Maritime Institute,” Scott explained, “working in two groups of three people.” The simulator sessions help lay the groundwork before getting aboard the real tug. “The simulator gets you the fundamentals,” says Armstrong, “but there are big blind spots aft looking to port and starboard, so that limits some of the things you can do with it.”

Once the North Arm Tempest was launched, and after Scott handled the stick work for sea trials, Armstrong and Maxwell were able to take the helm for real. “The challenge for folks moving from conventional tugs,” notes Scott, “is that their first instinct is to turn the nozzles the wrong way. You have to think of it as driving a big outboard-powered skiff with tiller steering – if you pull the tiller one way, the boat goes the other way.”

Complicating things is the fact that the two nozzles interact with each other and with the throttle. “You’re getting four reactions at once with two nozzles,” explains Scott. “So if you add a little throttle on one side, you’ll take away a little on the other.”

The hands-on training focused first and foremost on basic boathandling skills: coming alongside, flipping the tug around, walking it sideways, nosing into a barge. “If you don’t know how to drive the tug, you’re not going to be able to handle a barge,” comments Scott. “It’s a little humbling,” remarked skipper Brendan Maxwell during the first week of training. “You’re used to handling barges with ease, then suddenly you’re back to learning how to dock smoothly.”

Armstrong notes that the switch requires a combination of unlearning conventional tug habits and learning new Z-drive skills. “The conventional mindset can screw you up,” he remarks, “but once the new skills become second nature, there’s no problem switching back and forth – I got called out to work a night shift on one of the other boats and had no problem switching back.”

Armstrong and Maxwell agree that the phenomenal manoeuvrability of the azimuthing drives will create barge-handling options that didn’t exist before. “There’s a tendency to be cautious at first, approaching things with a conventional tug mindset,” says Armstrong, “but we’re noticing that we’re going to be able to approach jobs differently – it’s just a process of when we’re going to be able to adopt them.”

On-the-Water Performance

Following sea trials and initial training, the North Arm Tempest was initially put to work on the short-haul container barge run between Centerm in Vancouver and Duke Point in Nanaimo, and the big new tug is already proving its worth.

“The pulling power is great,” says Armstrong. “The container barge is bigger than the North Arm Genesis, and we’re definitely noting the upside of a bigger, more powerful tug – it’s a nice stable platform, which provides a level of comfort.” In terms of setup, the skippers noted that it would be nice to add tow winch controls to the upper helm station (the tug has controls for the hawser winch on the upper station, but not for the tow winch).

Free-running speed for the North Arm Tempest is about 10.5 knots, and they’ve been towing at about 7 or 8 knots. With only a few runs under its keel so far, detailed fuel consumption numbers haven’t yet been calculated, but preliminary figures appear to be in line with expectations. The next step will be for the North Arm Tempest tug to show its chops on the North Coast run, but the crew is already sold on the new tug.“You can’t see under the masks,” said Maxwell at the end of a recent run, “but we’re all smiles – it’s a great boat.”

Keep Reading