Power Take-Off Components

Understanding the essential components of power take-offs (PTOs) is crucial for proper selection, installation, and maintenance. This technical overview examines the key elements that comprise modern PTOs and how these components contribute to operational reliability and performance.

Engine Connection Systems

The interface between a PTO and the engine represents one of its most critical aspects. Industrial power take-offs offer numerous engine connection options designed to accommodate most industrial engines in the market.

SAE Housing Sizes

PTOs are manufactured to comply with standardized SAE housing dimensions, including:

- SAE 6

- SAE 5

- SAE 4

- SAE 3

- SAE 2

- SAE 1

- SAE 0

- SAE 00

These standardized housings ensure proper alignment and secure mounting to the engine flywheel housing, creating a stable platform for power transmission.

SAE Flywheel Sizes

Compatibility with various flywheel dimensions is equally important, with PTOs designed to accommodate standard SAE flywheel sizes including:

- 6.5"

- 7.5"

- 8"

- 10"

- 11.5"

- 14"

- 18"

- 21"

This standardization ensures that PTO clutch components properly engage with the engine flywheel, providing secure power transfer without misalignment issues.

Friction Plates

The internal mechanism of a power take-off relies on a clutch design utilizing friction plates that facilitate engagement and disengagement. Different friction plate styles serve specific purposes and application requirements:

One-Piece Organic Friction Plate

This represents the most common style, offering versatility and durability suitable for a wide range of applications. The one-piece design provides consistent wear characteristics and reliable performance in standard operating conditions. These plates balance performance with cost-effectiveness, making them suitable for most general-purpose applications.

Three-Piece Organic Friction Plate

Most frequently utilized in smaller PTOs, these plates are preferred by some operators for their ease of replacement. They eliminate the need for complete PTO disassembly during maintenance, reducing downtime and simplifying service procedures.

Sintered Iron Friction Plate

These heavy-duty friction plates provide enhanced torque capacity compared to organic alternatives; on average about 25% more torque. Typically incorporated in larger applications and bigger PTOs, sintered iron plates offer superior performance under high-load conditions. The metallic composition provides excellent heat dissipation properties, making these plates ideal for applications with frequent engagement cycles or sustained high-load operation.

Engagement Mechanisms

Modern PTOs offer various engagement mechanisms designed to meet different operational requirements and control preferences:

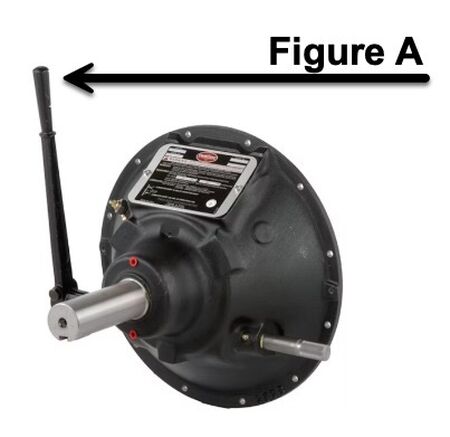

Hand Lever System

Traditional mechanical PTOs utilize a hand lever engagement system requiring manual operation at the equipment. This straightforward mechanism provides direct mechanical control of the clutch engagement process. The design typically incorporates an adjustment mechanism to compensate for friction plate wear over time, ensuring consistent engagement characteristics throughout the service life.

Hydraulic Actuation System

More modern PTO models employ hydraulic actuation for remote engagement. This system utilizes hydraulic pressure to control clutch engagement, enabling operation from a distance or from within an operator cab. Hydraulic systems typically incorporate self-adjusting mechanisms that automatically compensate for friction plate wear, reducing maintenance requirements and ensuring consistent engagement characteristics.

Bearing Options

Bearing selection and configuration significantly impact PTO performance and longevity, particularly in applications with a side load setup:

Standard Bearing Configuration

Most PTOs incorporate precision bearings that support the clutch shaft and manage operational loads. These bearings are sized and selected based on anticipated application requirements, providing reliable performance in standard operating conditions.

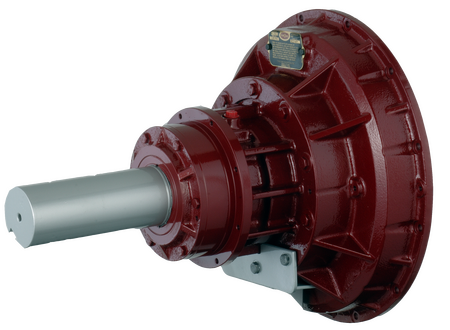

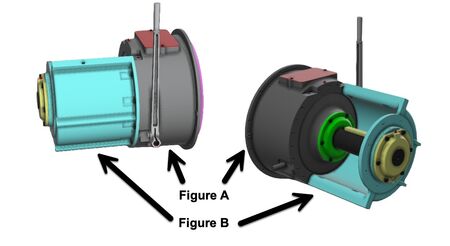

Straddle Bearing Design

Specialized applications with high side loads benefit from straddle bearing configurations. This design places large roller bearings on both sides of the support housing, significantly reducing shaft deflection and increasing torque capacity by approximately 25% compared to standard designs. The enhanced support structure makes straddle bearing PTOs ideal for demanding applications such as rock crushers and heavy-duty grinders.

Housing Components

PTO housings serve multiple critical functions beyond simply containing internal components:

Main Housing

The primary housing provides structural integrity and proper component alignment while protecting internal parts from contamination. Typically constructed from cast iron or aluminum alloys, these housings are designed to withstand operational stresses while providing necessary mounting points.

Support Sheave Housing

In straddle bearing PTOs, a specialized support sheave housing is used and it incorporates additional bearing support to withstand demanding side load applications. These reinforced housings accommodate the substantial lateral forces generated when using belt drives, ensuring proper alignment and component longevity.

The Bottom Line

The components that comprise modern power take-offs represent decades of engineering refinement aimed at delivering reliable performance in demanding industrial environments. Understanding these components—from engine connection systems to friction plates and bearing options—is essential for proper selection, installation, and maintenance.

For technical assistance with component selection or PTO configuration for your specific application, contact Palmer Johnson Power Systems. Our experienced team can provide guidance on component options that optimize performance and durability while meeting your operational requirements.

PTOs

Power take-offs enable power source disconnection in industrial and off-highway equipment for essential operations.

- What is a Power Take-Off (PTO)?

- Power Take Off Applications & Industries

- Power Take-Off Components

- How Does a Power Take-Off Work?

- Types of Power Take-Off (PTO)